Foamed polyurethane foam material for new energy

source: Foam Pageviews: time:Nov 10, 2022

describe:

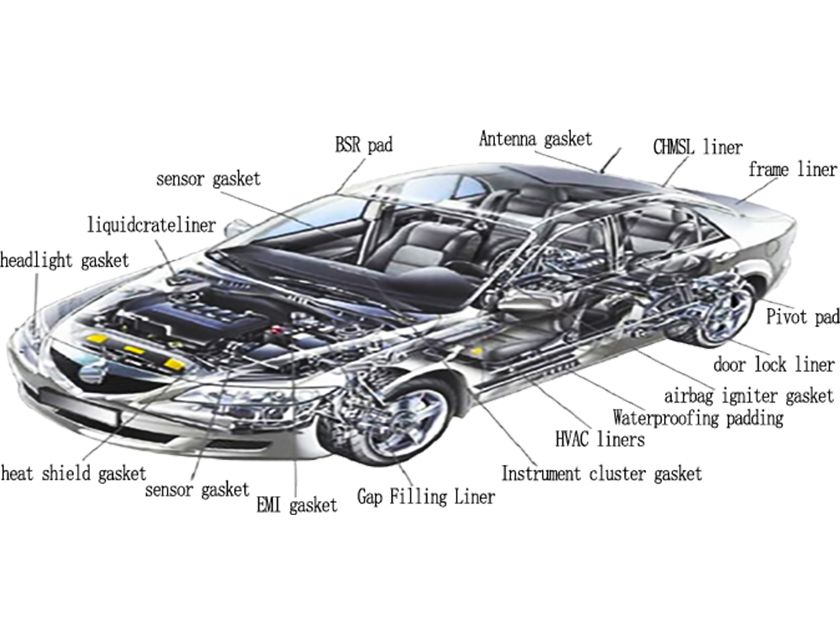

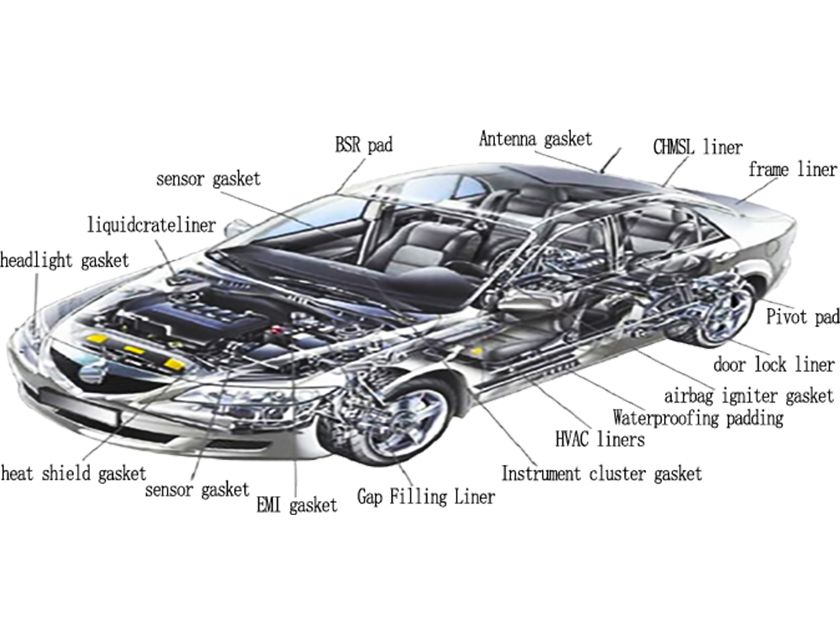

Polyurethane foam has excellent compression set resistance, ultra-high resilience, impact resistance, elasticity and durability. Polyurethane foam is widely used in the cushioning of new energy vehicles and electronic equipment interiors.

Foamed polyurethane foam material for new energy

Polyurethane foam is a material that has been foamed by plastic particles. It has a series of characteristics such as light weight, elasticity, fast pressure-sensitive fixing, convenient use, free bending, ultra-thin volume and reliable performance. And easy to compress, suitable for extreme environments that may have to be dealt with. Various applications including heat, vibration, dust, dirt and vibration.

Polyurethane foam materials maintain their integrity and effectiveness in caulking, gasketing and vibration isolation applications. It can meet the requirements of fixing and sealing of smooth parts of various parts, and is suitable for non-structural fixing and sealing of light and small materials.

Polyurethane foam material plays a vital role in the power battery of new energy vehicles, which is related to the safety of the battery pack and the whole vehicle. The cooling system inside the battery pack has been converted from traditional air cooling to liquid cooling, but the liquid cooling plate Direct contact with the battery pack will cause the liquid-cooling plate to be in a load-bearing state for a long time. In addition, it is an alloy structure, which will cause certain physical deformation. There will be a certain collapse in the middle position, resulting in gaps in the contact interface with the battery module. , which is not conducive to the transfer of heat, which requires corresponding support for the liquid-cooling plate structure to prevent the deformation of the liquid-cooling plate structure, so that the battery module can be seamlessly connected to facilitate heat transfer.

Polyurethane foam is widely used for cushioning in new energy vehicles, electronic equipment, and interiors of aerospace and rail vehicles. With flame retardant, wear resistance, heat resistance, cold resistance, cushioning, sound absorption, shock resistance, sealing, such as excellent compression deformation resistance, ultra-high resilience, impact resistance, elastic durability, etc., durable. Polyurethane foam material also has excellent resilience, good vibration damping and shock absorption properties, and excellent waterproof sealing effect. It is available in a wide range of hardnesses and thicknesses and is easy to compress for applications requiring high flexibility.

The product series includes SRO15P series ultra-soft polyurethane foam, SRO40P series soft polyurethane foam, SRM50P series fast rebound polyurethane foam, SRH60P series rigid polyurethane foam

Features:

• Rich thickness, the thickness of 0.10~4.00mm provides options for various spaces that need to be filled

• Good sealing, can provide good dust sealing effect for equipment under moderate compression

• Long-lasting elasticity, providing long-term stable positioning for parts that need to be fixed

•Super soft and compressible, the compression ratio is up to 90%

• Strong surface, easy to match with protective film, not easy to chip

• Good shock absorption performance, can effectively protect components and reduce impact damage

• Excellent resistance to compression set, providing long-term protection for equipment

Advantage:

• Flexibility to adapt to various environments

• Flexible and compressible for a protective seal with minimal force

• High compressibility allows material to fit into gaps of different widths for greater design flexibility

• Reduced maintenance costs due to gasket failure due to compression set and softening

• Excellent durability

• Noise reduction possible

Scope of application

•Mobile phone speakers, power modules, lampshade seals, automobiles, electronic equipment and computer communication equipment and other industries

•Fixed bonding and protection of electronic products, cameras, speakers, LCD monitors, signs, etc.

•Battery, press the foam on the plug

• Computer, electronic equipment foot pads, etc.