Application of Polyurethane Foam in Display

source: Foam Pageviews: time:Nov 01, 2022

describe:

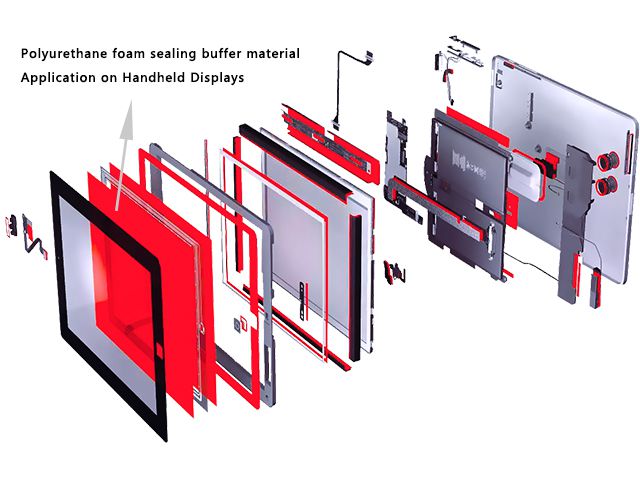

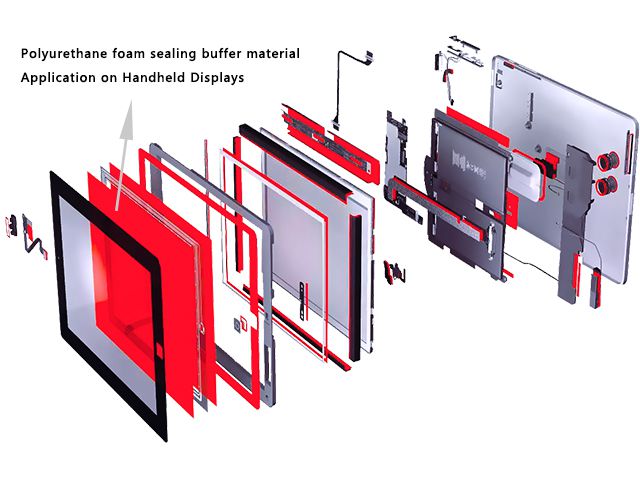

Polyurethane foam provides a thin, soft seal and cushioning protection for handheld device displays. Polyurethane foam materials are used in electronic devices to absorb and disperse impact energy, protecting displays from shock, dust, moisture and pa

Application of Polyurethane Foam in Display

Polyurethane foam provides a thin, soft seal and cushioning protection for handheld device displays. Thinner profiles, variations in manufacturing tolerances, temperature fluctuations, water resistance and drop testing all add to the difficulty of designing a display protector for portable devices. Polyurethane foam materials are used in electronic devices to absorb and disperse impact energy, protecting displays from shock, dust, moisture and particles.

Main features

1. It has excellent sealing performance to avoid gas release and atomization.

2. Compression deformation resistance, that is, elasticity is durable, which can ensure long-term shock protection of accessories.

3. It is flame-retardant, does not contain harmful substances, does not remain, does not pollute equipment, and is not corrosive to metals.

4. Can be used in a variety of temperature ranges. It can be used from minus 40 degrees Celsius to 90 degrees.

5. The surface has excellent wettability, easy to bond, easy to manufacture and easy to punch.

6. Engineering polyurethane formulation provides a wide range of modulus - 2-90psi@25% deviation - to meet more design flexibility requirements

The main purpose

(1) Panel interlayer: function - no pollution, prevent loosening, prevent impact noise, and prevent sticking.

(2) Around the LED: prevent light leakage, absorb shock, and improve air tightness.

(3) Lower periphery of PCB: shock absorption, vibration absorption, gap filling, thermal insulation effect.

(4) Keyboard gasket: rebound, no pollution, good dimensional stability.

(5) Around the battery: no pollution, absorb impact sound, improve air tightness.

(6) Foot pads: good friction, no pollution and good dimensional stability.

(7) The rear pad of the disk drive: absorbs vibration, prevents impact noise, and improves air tightness.

(8) Friction pad: good friction, no pollution and good dimensional stability.

(9) Disc cover cushion: absorb vibration, block motor noise, shockproof, and improve air tightness.

(10) Around the speaker: prevent noise and fill the gap.

(11) Around the LCD: dustproof, shock absorption, gap filling, and light-shielding improvement.

shock protection

To protect the display from shock and vibration, the display or LCD gasket must absorb and disperse the shock energy to prevent cracks or other damage from mechanical shock. Polyurethane foam material absorbs and dissipates impact energy, helps prevent unwanted cracks on the display, and provides excellent protection against mechanical shock and impact damage.

Monitor back pad

For touchscreens on tablets and other devices, the display backing pad helps achieve an excellent cushion seal for long-term reliability. Back liner applications require the use of extremely soft materials that disperse forces, provide good compression set resistance and compressibility, have low resilience and good stress relaxation resistance. For many touch screen back pad applications, KTS series polyurethane foam is a good foam material.

Ruggedized Display

In outdoor or industrial touchscreen applications, LCD displays must withstand vibration, physical shock, and temperature fluctuations, while providing highly conformable sealing and caulking properties. Good vibration isolation and shock absorption performance can be achieved under severe conditions.