Application of Silicone Foam Materials in New Energy Vehicle Batteries

Silicone foam materials can play a distinctive role in the application of new energy production of chassis, engine brackets, ventilation and air conditioning equipment, and batteries. It produces a very consistent rebound force within a certain compression range in caulking applications. Silicone foam can withstand the collapse caused by compressive ground stress and temperature during the entire application process.

In recent years, my country's layout of the new energy vehicle industry and the orientation of relevant policies, the total supply and sales have continued to grow, and the industrial development has continued to accelerate, which has also promoted the upgrade of the safety factor of new energy vehicle components.

At present, pure electric vehicles mainly use lithium batteries as power batteries. After many years of development trends, the safety factor of lithium-ion battery power batteries has already been significantly improved. However, under the extreme standard, lithium batteries still have the risk of ignition and explosion. Lithium battery fires or explosions have become the most critical technical reasons for safety accidents in new energy vehicles. There are two ways to reduce and eliminate such safety accidents. One is to change the lithium battery itself, and the other is to use new materials with fire-retardant and flame-retardant properties. At this stage, there are five kinds of power batteries popular on the market: lead-acid battery, lithium titanate, lithium cobaltate battery, lithium iron phosphate battery, nickel-cobalt-manganese, and nickel-cobalt-aluminum. Among them, lithium iron phosphate battery and ternary lithium battery are also the most popular popular power devices used in battery cars at this stage. In a short period of time, it is impossible to find new materials to change or even replace the lithium battery itself.

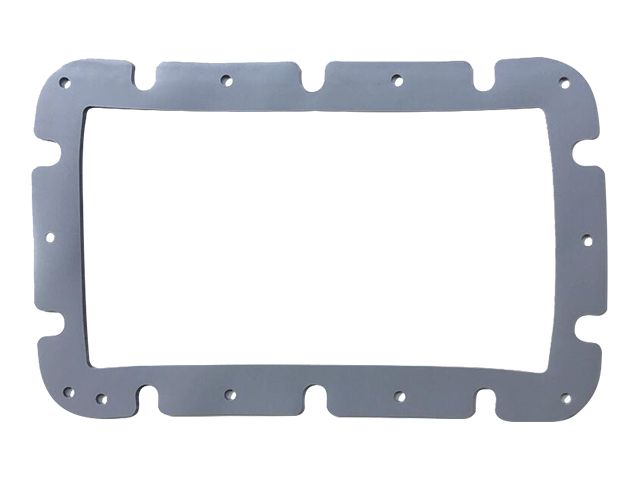

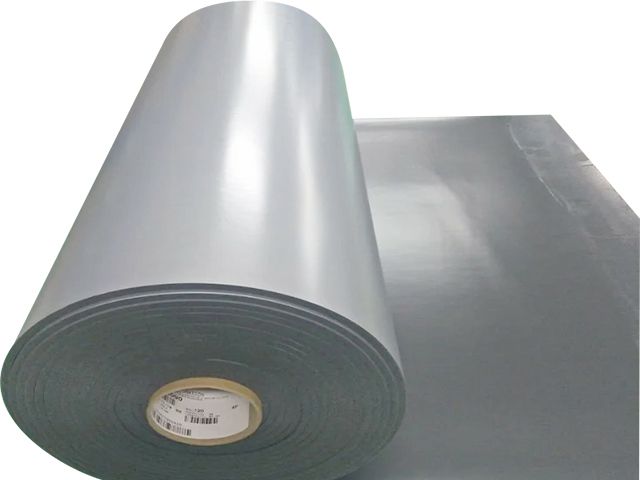

The key energy source of new energy vehicles is the car battery pack, which drives the electric energy for the whole vehicle. In order to protect the electronic components inside the battery pack from factors such as dust, precipitation, shock resistance, etc., the sealing of the casing of the battery pack must consider flame retardancy and heat resistance, low heat transfer coefficient, no harmful gas, waterproof and shock resistance, light weight and thickness, and price. Advantages of six functions. Therefore, the waterproof sealing design scheme of the battery pack is very important. Silicone foam has high-quality physical properties, extraordinary electrical equipment characteristics and reliable performance, and can reasonably handle the sealing and shock absorption of the left and right casings of the new energy vehicle battery pack and the shock absorption of the support points of the auto parts.

Silicone foam is non-toxic, odorless, and has good flexibility. Long-term application without deformation, shrinkage resistance, corrosion resistance, aging resistance, UV resistance. Heat resistant (up to -40~220℃). Therefore, it has become the best choice for the ultra-thin and most efficient thermal insulation and waterproof sealing of new energy vehicles and power batteries. Silicone foam is also widely used to fill light leakage, anti-fouling, impact absorption, and improve sealing around LEDs, as well as to prevent noise and fill gaps around audio speakers and speakers.

|

|