The application of silicone foam in the sealing and shockproof of new energy vehicle battery packs.

The electric vehicle power system is a complex structure combining mechanical and electrical, and its stiffness, strength, vibration, and service life should be fully considered when designing.

With the urgent demand for electric vehicles for high energy density and short time charging, the application of ternary cathode materials, and fast charging technology makes lithium-ion batteries very easy to mechanical abuse, electrical abuse, and thermal abuse, which leads to thermal runaway of the battery system and fire and explosion of the whole vehicle, so the powerful lithium-ion battery has become a hot spot and difficult point of research in the field of new energy vehicle power system.

The battery pack case (shell) is the main load-bearing component of the battery pack, only the static and dynamic (rigid strength, modal, etc.) stability of the case can ensure that the power battery does not appear in abusive conditions so that the power system runs smoothly.

Battery pack case material should have electrical insulation, high heat dissipation, chemical stability, etc. The case is generally composed of upper and lower case and a sealing system. The mass of the battery pack accounts for 18% to 30% of the overall vehicle system mass, while the mass of the case body accounts for about 10% to 20% of the total mass of the battery pack. At present, metal is commonly used as the battery pack case material, and composite materials are also gradually gaining attention due to their excellent specific rigidity strength.

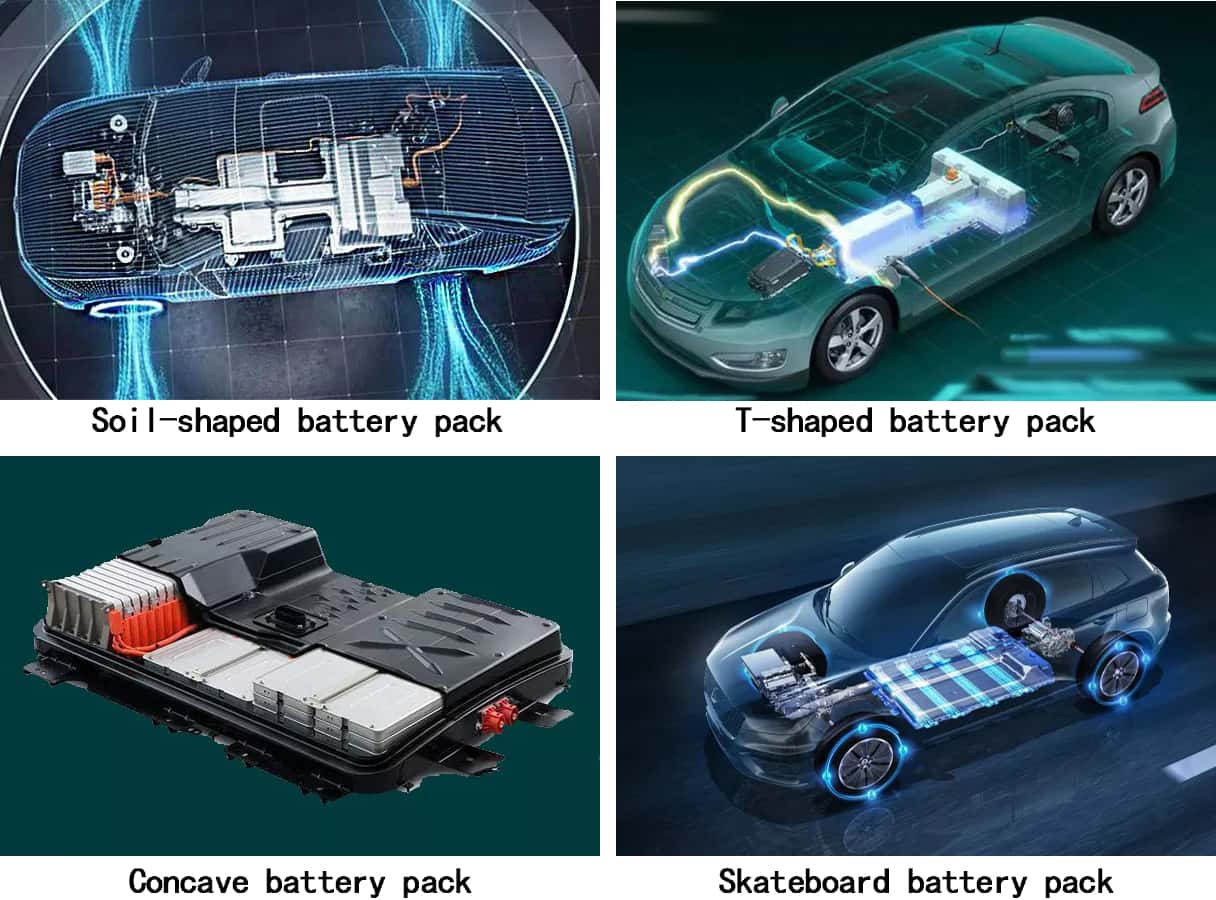

The design of the new energy vehicle power pack case needs to consider the internal heat dissipation, water, and dust resistance, and safety of the battery pack, so the design that takes into account the lightweight and other performance balance of the power pack will be an important challenge. At present, the battery pack structure of new energy vehicles mainly has "earth" type, "concave" type, "T" type and "skateboard "The shape and arrangement are mainly influenced by the development platform of the model, and the different battery pack structures are shown in the figure:

The following are the battery pack arrangements for different brands:

| Brand and model | Battery Pack Arrangement |

|---|---|

| Tesla Model Series | Rectangular base plate integrated with body floor |

| Chevrolet Volt | Underbody, "T"-shaped |

| BMW 3 | Rectangular base plate integrated with the underbody |

| Ford Focus-EV | Front of rear axle |

| Renault Z0E | Rectangular base plate integrated with underbody |

| Volkswagen e-Golf | Under the chassis, "earth" shape |

| Nissan Leaf | Under the middle chassis of the car |

| Audi AL e-tron | T-shape in front of the rear axle in the floorboard |

| Honda Fit | Under the middle floor of the body |

| Xiaopeng G3 | Underneath the floor plate heart automotive material net |

Our company specializes in providing battery pack sealing materials. Silicone foam has excellent sealing, is fireproof (UL 94 V-0), shockproof, and heat dissipation characteristics, and has different hardness and thickness to meet diversified needs, can be customized into different shapes to meet the requirements of different models, different shapes of battery pack sealing. Silicone foam can make the battery pack more lightweight and safe.