How to judge the quality of silicone foam material die-cutting and punching gaskets!

Silicone foam gasket is a type of foam material widely used in electronic and electrical equipment. Silicone foam gasket can be used in new energy vehicles, electronic equipment, aerospace and rail vehicle interiors, providing more effective equipment for equipment. buffer protection. With the increase in market demand, the demand for silicone foam gasket materials for new product research and development has increased, and more and more consumers are also difficult to choose products. How to choose high-quality suppliers and silicone foam Gaskets became the problem!

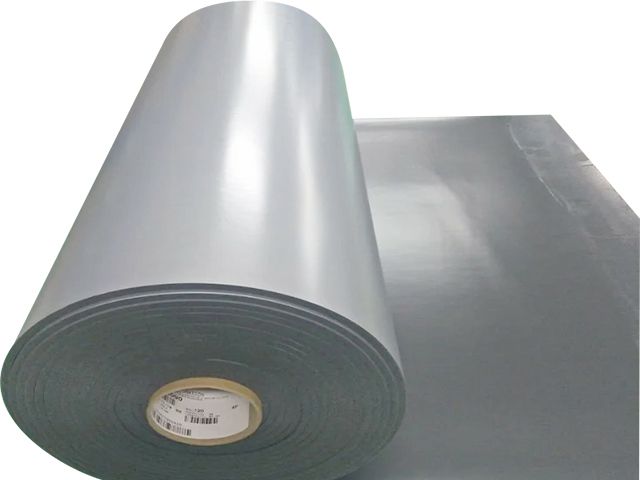

The quality of silicone foam gaskets is very important, so high-quality silicone foam gasket manufacturers are naturally indispensable for high-quality silicone foam materials. Thickness is the key issue. This phenomenon occurs in many silicone foam materials. There are errors in the thickness of large-area foam materials. The middle thickness is thin on both sides, and the single side is thin and thick on both sides. The subsequent cracking phenomenon, the soft deformation of the product and the poor tensile resilience are all quality problems.

Therefore, first determine whether the manufacturer's silicone foam material is genuine and whether the quality is guaranteed. Before deciding to customize the manufacturer's silicone foam gasket, adjust the machine, mold workmanship and product raw materials during the processing of the silicone foam gasket die-cutting manufacturer. Control. All of the above may affect quality problems, and normally these problems can be completely controlled.

Secondly, the production equipment and scale of silicone foam materials involve the production capacity of the product. If the purchase volume is relatively large and the delivery time is relatively tight, it is necessary to find a large-scale and experienced manufacturer. Every high-quality supplier will achieve the ultimate after-sales service, so when choosing a supplier, you should first ensure the delivery of the goods and the follow-up quality problem processing and feedback speed.

|

|