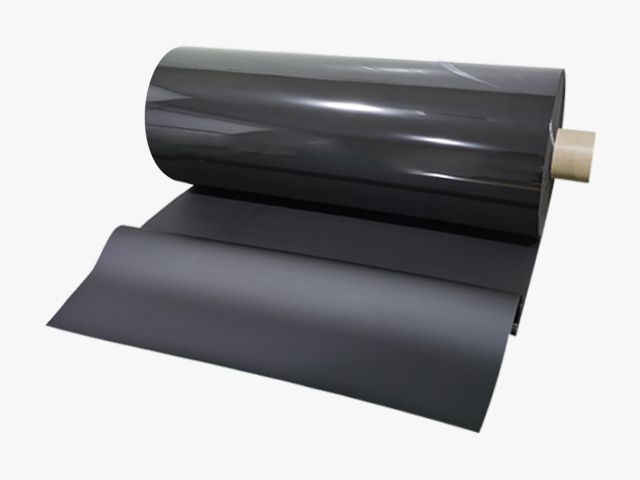

The application and processing technology of polyurethane foam is introduced in detail!

Polyurethane foam is a foam material with excellent performance. It is suitable for cars, electronic devices, mobile phones, notebook computers, refrigerators, and central air conditioners. It is also suitable for external dispensing, production and processing, and customization and punching of related products. Heat-resistant to 150℃, ultra-low temperature to minus 40℃. It also has an irreplaceable effect in the die-cutting production and processing of auxiliary materials for electronic devices.

Polyurethane foam features:

1. Specifications and models: 0.79mm, 1.57mm, 1.14mm, 2.36mm, 6.35mm, 12.7mm, 4.78mm, 9.53mm, 0.53mm, the length and overall width can be manufactured according to actual regulations.

2, color: black, gray.

3. Adhesion: high adhesion, high external force, temperature resistance and acid resistance. The thickness of the super glue applied varies. Silicon vulcanized rubber is used for the second layer; it is used for converters, small computer keyboards, and electronic device components.

4. Wear resistance, high temperature resistance, low temperature resistance, cache, sound insulation, shock resistance, sealing; such as excellent shrinkage resistance, extremely high resilience, impact resistance, elastic continuity, etc., are widely used in various Anti-seismic effects of fine commodities.

Scope of application:

①Control panel compartment: zero pollution, avoid loosening, avoid collision noise, avoid sticking.

②LED periphery: avoid light transmission, absorb shock, and single high sealing.

③ Near the bottom of the PCB: the actual effect of absorbing shock, absorbing vibration, making up for gaps, and thermal insulation.

④Keyboard gasket: anti-ductility, zero pollution, good specification and reliability.

⑤ Surroundings of rechargeable batteries: zero pollution, absorbing impact sound, and improving sealing.

⑥ Seat cushion: good friction coefficient, zero pollution, good specification and reliability.

⑦Disk drive end sanitary napkin: absorb vibration, avoid collision noise, and improve sealing.

⑧ Friction washer: good friction coefficient, zero pollution, good specification and reliability.

⑨ Disc cover sponge pad: absorb vibration, block motor noise, shock resistance, and improve sealing.

⑩Audio speakers: avoid noise and make up for gaps.

LCD Peripheral: Anti-fouling, absorbing shock, filling gaps, improving light blocking.

Application in the car industry:

1. High brake light: waterproof and light blocking;

2. Light-emitting diode and operation panel gasket: gasket;

3. Rear view camera and flashing signal indicator: waterproof, anti-fouling, gasket;

4. Reversing camera: waterproof and anti-fouling seal;

5. Shift door handle: cache;

6. Lithium battery pack: natural environment seal/spacing.

Application on power lithium battery:

Advantage:

1. A variety of thin and thick choices;

2. Excellent heat transfer;

3. Excellent shrinkage characteristics and resilience;

4. The flame retardancy is UL94-V0;

5. Comply with Rohs specification.

Application on high-speed trains:

Exhaust system software seals, display seals, lighting cabinet seals, HVAC engineering seals, sound and noise reduction, overhead seals, door seals, dampers and under desk seals, caulking, seat foam, aluminum silicate Fibers, electrical control cabinet seals, fluctuating wood flooring materials.

Die cutting of polyurethane foam:

1. Machinery and equipment: rotary die-cutting machine

Production and processing method: roll cutting

CNC blade: metal material hand-carved round blade

Application: complicated processing technology, die-cutting of many manufactured goods

2. Material details:

Self-adhesive, protective film, sponge, wire mesh, metal foil, composite, double-sided tape;

3. Detailed introduction of processing technology:

Dividing - Rolling - Compounding - Die Cutting

segmentation

Raw material distributors typically have a very small number of standard-sized rolls of material. Materials of this specification cannot generally be used, and the length and overall width do not meet the production and processing regulations. At this time, you can change the length and overall width of the material roll according to the rewinding/segmentation to consider the production and manufacturing regulations. We can divide a wide variety of materials. For example: plastic film, paper, cloth, pharmaceutical tape and industrial production tape.

Rewinding/Slitting: Methods - Longitudinal Section

Machinery and equipment - rewinding and slitting machine, rotary die-cutting machinery and equipment

CNC inserts - cutter head, grooving cutter head, air cutter head

Application - slitting of PET film, paper, composite materials, etc.

Die-cutting process analysis (picture):

segment:

Method: Cross-section

Machine equipment: automatic cutting table

CNC blade: beef rib kitchen knife, white steel single and double-edged knife, round knife

Application: Cut and roll tape, foam, protective film, etc.

Compound:

Using pressure-sensitive tape as a medium, two or more materials are bonded together, and the composite material has the characteristics of a variety of materials, making non-pressure-sensitive materials more and more pressure-sensitive and self-adhesive. This type of processing can produce non-standard materials to incorporate requirements that cannot be considered with a single material.

Method: press fit

Machinery and equipment: cross-cutting machine, rotary die-cutting machine and equipment

Application: plastic foam, plastic sheet, plastic glue, etc.

Die-cutting production Before manufacturing, composite or composite die-cutting is additionally produced and processed.

|

|