Application of silicone foam in new energy vehicle power battery

source: Foam Pageviews: time:May 13, 2022

describe:

Silicone foam material has the characteristics of good shockproof buffer,sound insulation,heat insulation,flame retardant and explosion-proof.Silicone foam is suitable for new energy vehicle battery sealing gasket,automobile shock absorption,etc.

Application of silicone foam in new energy vehicle power battery

Introduction to Silicone Foam

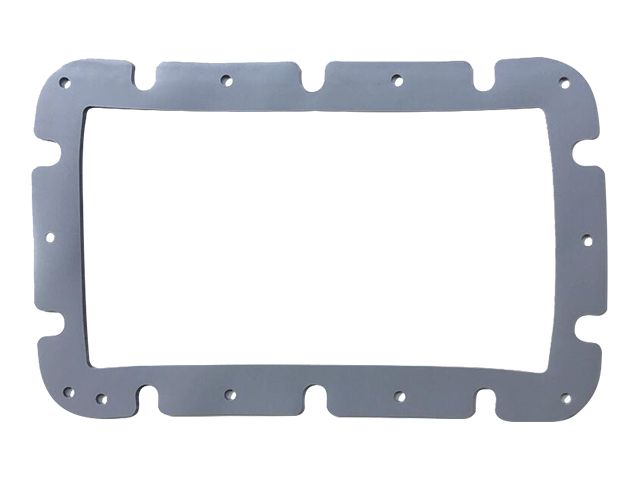

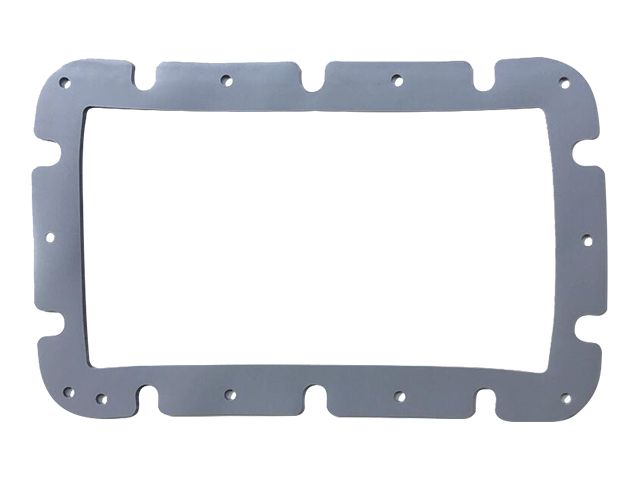

Silicone foam material (also known as: silicone foam/foamed silicone) is made of silicone rubber raw rubber, fillers, vulcanization accelerators, foam rubber, etc. as raw materials. A porous, low-density, compressible polymer elastomer made at high temperature. Due to the high elasticity of silicone rubber and the sound insulation and shock absorption properties of foam materials, it is widely used in life and is mostly used as vibration damping pads, sealing gaskets, sound-absorbing materials, insulating layer materials, and airline insulation materials. . According to the cell structure, silicone foam is divided into three types: closed cell type, open cell type and mixed type.

The closed-cell foamed silicone foam material has the characteristics of good shockproof buffer, sound insulation, heat insulation, flame retardant and explosion-proof, etc. Foamed silicone gaskets for energy vehicle batteries, etc. Many interior materials of today's automobiles, such as floors, ceilings, steering wheels, and car seats, are all polyurethane foam materials. Because the price of polyurethane foam material is lower. However, polyurethane-based foam materials have poor weather resistance, are flammable, and release a large amount of toxic gases that are harmful to the human body during combustion. Therefore, with the promotion of silicone foam materials and the improvement of people's understanding of them, silicone foam materials are expected to replace traditional polyurethane foam materials in the future.

Features of Silicone Foam

The density of silicone foam

The density of the silicone foam matrix is 1.17g/cm3. However, through foaming treatment, the density of the silicone foam material prepared in the current mature process can be as low as 0.16-0.20 g/cm3, which can be used for parts such as car seats and headrests; while the conventional silicone rubber foam material (density of 0.45 g/cm3) is widely used for gap filling in sealing, shock absorption and other parts.

Flame Retardant Properties of Silicone Foam

According to scientific experimental research data, the silicone foam added with flame retardant has good flame retardant performance, and the flame retardant grade can reach UL94-V0. When applied to electric vehicles, it can reduce the damage caused by combustion. question.

Electrical insulating properties of silicone foam

With the increase of the amount of physical filler, the volume resistivity and surface resistivity of silicone rubber tend to decrease, and the dielectric constant and dielectric loss factor generally tend to increase. It can be seen that the addition of physical fillers impairs the electrical insulating properties of silicone rubber to a certain extent.

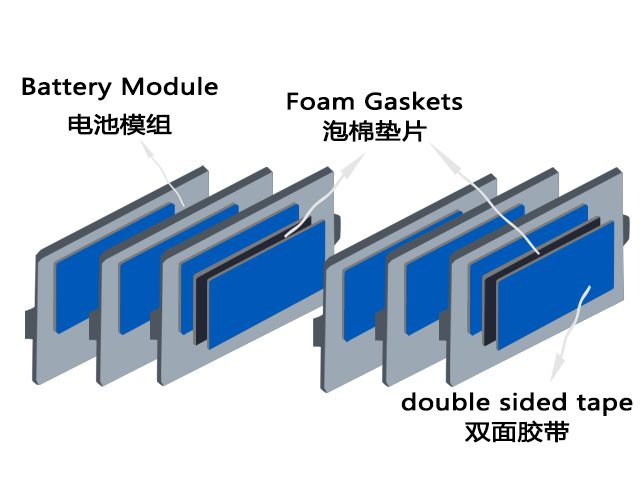

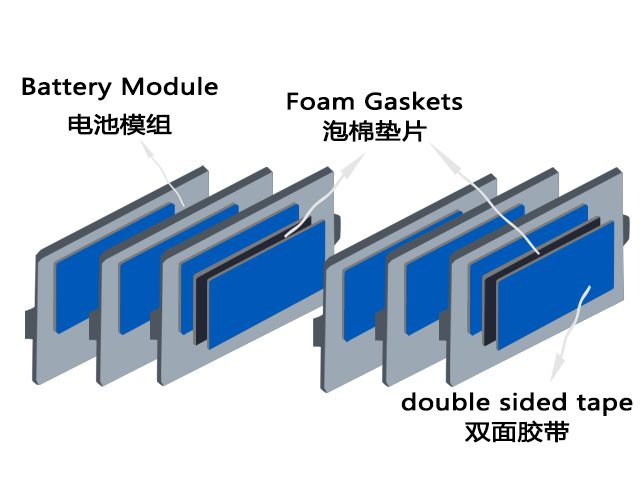

Application of Silicone Foam in Electric Vehicle Industry

The battery cell is the source of kinetic energy for pure electric vehicles. The safety hazard of the battery cell seriously endangers the safety of the whole vehicle. When the battery cell is working, it will generate a certain amount of heat, and it can produce a certain thermal expansion and contraction effect at different temperatures. , causing the cells to expand to a certain extent, and the long-term capacitance grid friction between the cells is likely to cause damage to the cells and cause the rechargeable battery to be invalid, and even uncontrollable in severe cases. In addition, the output voltage of the battery pack is above 200V. It is stipulated that the rechargeable battery case must be sealed and waterproof to avoid circuit short circuit caused by water seepage. The waterproof level of the rechargeable battery case is required to be IP67.

Silicone foam has the characteristics of high reduction and reduction. It avoids the deformation caused by the thermal expansion and contraction of the rechargeable battery Cell during the whole process of battery charging, charging and discharging. It has excellent durability, low shrinkage, and impact digestion and absorption. and flame retardancy (UL 94 V0 rating). At the same time, silica gel also has good waterproof performance, as well as the following properties, so it is widely used in the cache thermal insulation and outer frame sealing of new energy cells.

1. At different temperatures, the performance of the silicone foam is stable, and the performance of the commodity sealing ring is stable

2. Excellent waterproof sealing, no water seepage when the product is used outside

3. The long-term shrinkage damage is small, and it has a certain working ability to curb shrinkage and deformation.

4. Excellent flame retardant performance, which can effectively prevent the risks caused by thermal effects during battery operation

5. The thickness and strength can be designed according to different standards. The sealing ring must be well matched with the housing and have low internal stress, which can effectively avoid the sealing ring from bending and arching.