Application and characteristics of tsr-10 polyurethane foam

The main chemical component of tsr-10 polyurethane foam is polyurethane (PU foam). After physical foaming, it does not contain foaming agent, and uses low-density formula and special surface treatment technology to achieve both good sealing and shockproof performance and scratch resistance.

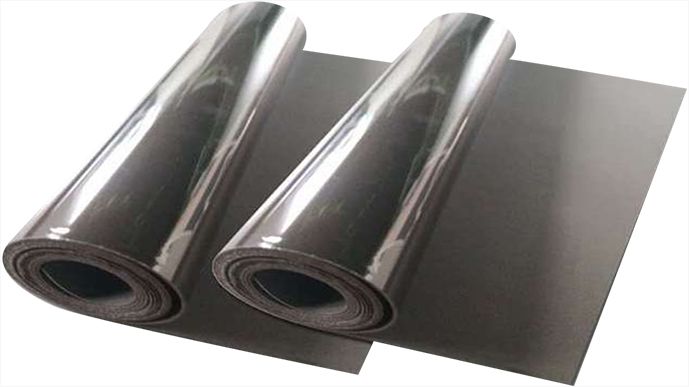

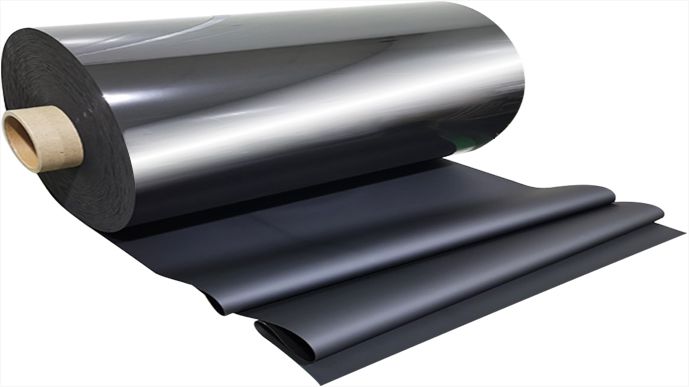

Various thicknesses of PU foam commonly used in the market at present:

0.2/0.3/0.4/0.5/0.6/0.7/0.8/1.0/1.2/1.5/2.0/2.5/3.0mm

Otto polyurethane foam subverts the industry and pursues excellence. At the same time, it has developed the industry's thinnest thickness of 0.1/0.15mm to solve the industry's confusion about high thickness requirements.

Main purpose:

• panel interlayer: function - no pollution, prevent loosening, prevent impact noise and prevent adhesion.

• around led: prevent light leakage, absorb impact and improve air tightness.

• lower periphery of PCB: absorb impact, vibration, fill gap and heat insulation effect.

• keyboard gasket: anti elastic, pollution-free and good dimensional stability.

• around the battery: no pollution, absorb impact sound and improve air tightness.

• foot pad: good friction, no pollution and good dimensional stability.

• rear pad of disk drive: absorb vibration, prevent impact noise and improve air tightness.

• friction gasket: good friction, no pollution and good dimensional stability.

• disc cover cushion: absorb vibration, cut off motor noise, prevent vibration and improve air tightness.

• around the horn: prevent noise and fill the gap.

Main features:

• excellent sealing performance to avoid gas release and atomization.

• compression deformation resistance, i.e. the elasticity is durable, which can ensure the long-term shockproof protection of accessories.

• it does not contain harmful substances, does not remain, does not pollute the equipment, and is not corrosive to metals.