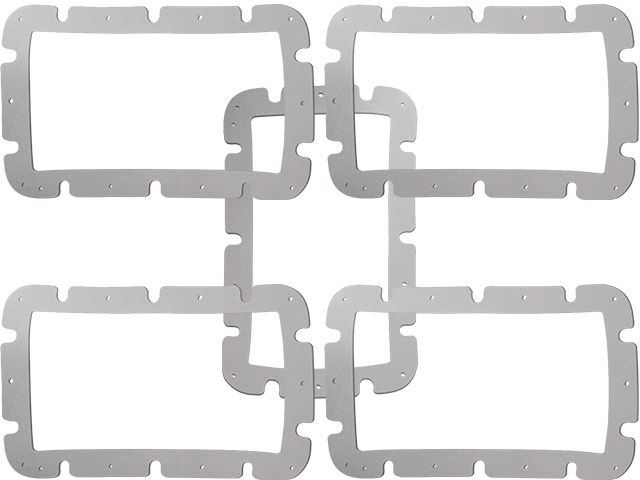

Electric vehicle battery silicone foam gasket material combination

The product portfolio of silicone foam gasket materials for electric vehicle batteries is designed to provide a complete solution for the cushioning and vibration isolation of lithium-ion batteries, including expanded product capabilities, enabling it to provide customers with customized compressive stress curves to meet specific design criteria. With their high energy density and charging efficiency, lithium-ion batteries are the ideal energy source for next-generation electric, hybrid and plug-in hybrid vehicles. However, these batteries also present a set of challenges for safety, longevity and performance that require silicone foam materials to address.

Silicone foam materials have been widely used in the industry. Silicone foam can generate stable rebound stress within a certain compression range, so it is especially suitable for ensuring the safety and reliability of electric vehicles during their service life. The compression curve of the silicone foam shows the material's advantage in withstanding long-term compression and temperature. This is critical to ensure stable performance over the life of the battery. At the same time, silicone foam also extends the life of electric vehicle batteries by shock absorption and protection of sensitive components.

By drawing on many years of experience in cooperation with key partners in the automotive and battery industries, our company has been able to rapidly develop prototype products with customized compression curves that can work within the necessary constraints of cell design, and achieve greater improvements at the source of battery design. Good prediction of material shock absorption and cushioning properties to help optimize battery efficiency and improve long-term reliability.

Silicone foam has the functions of sealing, shockproof, waterproof, dustproof and heat insulation, and also has excellent temperature and UV resistance.