Advantages, disadvantages and uses of high thermal conductivity silicone foam

source: Foam Pageviews: time:May 24, 2022

describe:

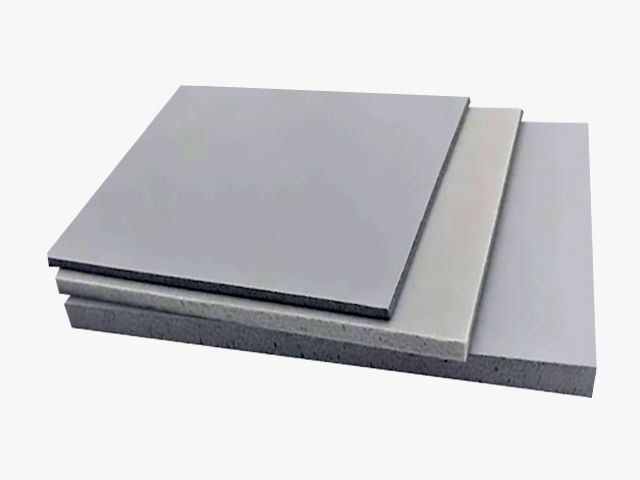

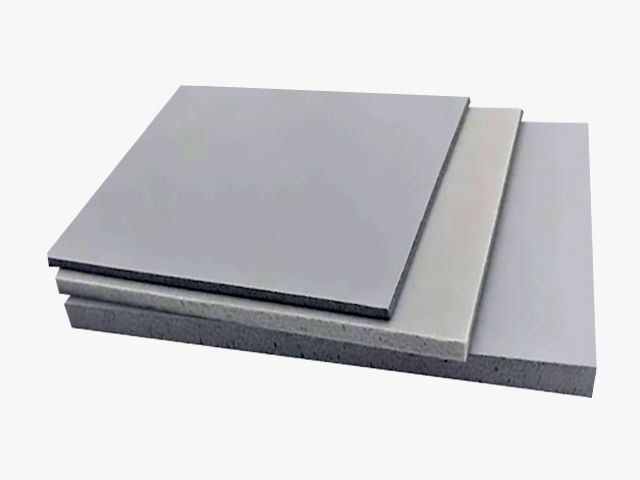

Silicone foam material,high density,fine and uniform cell structure,excellent resistance to compression deformation.Widely used in the sealing and shock absorption of mobile phones,communications,computers,electronic and electrical components.

Advantages, disadvantages and uses of high thermal conductivity silicone foam

Silicone foam material, high density, fine and uniform cell structure, excellent resistance to compression deformation. Widely used in the sealing and shock absorption of mobile phones, communications, computers, electronic and electrical components. Silicone foam is very soft and easy to compress, and is suitable for applications with high compressibility requirements.

Silicone foam has soft series materials, quick rebound series materials, and hard series materials. Energy management for gasket applications. Provides a higher level of vibration isolation protection for extreme demand environments.

Silicone foam provides good shock absorption, buffering, impact resistance and other properties for industrial production parts

In the field of vehicle, electronic equipment manufacturing and aerospace, the high-efficiency shock absorbing material of silicone foam must be able to withstand the hazards caused by shrinking and repeated use, and also handle and absorb the devastating impact kinetic energy. Silicone foam material provides good shock absorption, absorbs and disperses impact kinetic energy, and protects components from working pressure. Most shock-absorbing cushions will be damaged after a period of application, but the silicone foam material has excellent air permeability due to its unique perforated structure, and will not be damaged after continuous application. These silicone foam materials have excellent fluid density and conformability, and resist shrinkage and stress relaxation. Silicone foam material can provide the coordination ability, long-term shock resistance and excellent shock absorption effect required for daily necessities design.

Foam Features:

• Very good shielding effect at low pressure, the shielding effectiveness exceeds 90dB.

• Flexible and lightweight.

•Anti-corrosion nickel coating provides protection against galvanic corrosion.

• Low surface contact resistance.

• Quick pressure-sensitive fixation.

•Customer can specify length.

• Numerous section options.

• UL class fire protection.

Can be pasted with Mylar (Valet double-sided tape) product quality is stable,

Heat-resistant pressure, not easy to fall off, high tensile strength,

After the product is installed, at a low temperature of -20 °C to a high temperature of 80 °C,

The quality of the cycle test is still maintained for 72 hours.

It has the advantages of convenient use, free bending, ultra-thin volume,

Reliable performance and a series of characteristics.

Compression options for polyurethane foam seals:

The tightness of the foam is a very important indicator in the design.

1. Sealing against dust and water droplets: 5% compression.

2. Sealing against water (10cm): 30% compression

Sealing performance can be improved by:

Increase the amount of compression: The higher the amount of compression, the better the seal can be.

Skinned Foam Surfaces: Products with skins reduce the chance of contact surface leakage.

Taped: Double-sided tape reduces the chance of contact surface leaks, even if the compression is small.

Consistent resilience: All contact surfaces are guaranteed to be resilient.

Increase the foam area: Increase the path that the leak has to travel.

Application range:

•Mobile phone speakers, power modules, lampshade seals, automobiles, electronic equipment and computer communication equipment and other industries

•Fixed bonding and protection of electronic products, cameras, speakers, LCD monitors, signs, etc.

•Battery, press the foam on the plug

• Computer, electronic equipment foot pads, etc.