Application of silicone foam in sound insulation and noise reduction in aircraft interiors

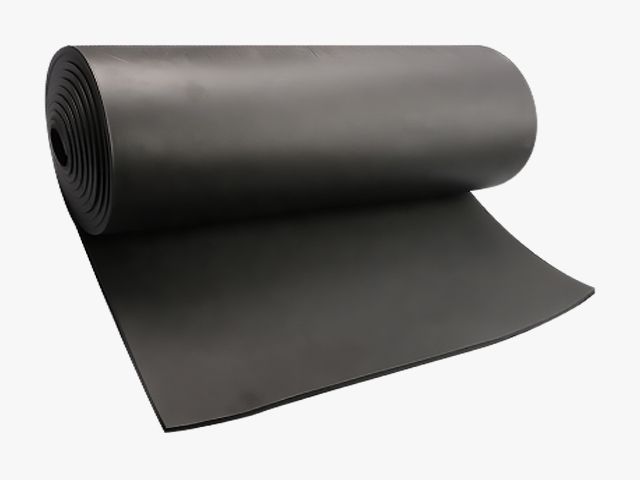

Silicone foam materials for aerospace aircraft interiors offer a long-term solution to reducing vibration and noise, and can withstand harsh conditions at extreme temperature standards and in terms of flame retardancy. Silicone foam exhibits excellent performance in reducing low frequency noise.

Vibration management is an important part of design products in the transportation, daily necessities and industrial production and sales markets. Vibration is likely to cause nasty noise and damage electronic components. Silicone foam high resilience material can handle noise and vibration problems in important applications. Silicone foam is a polyurethane elastomer with high resilience. It is especially suitable as a vibration isolation and noise reduction material. This unique material has the ability to resist compression deformation, and has excellent resilience, excellent shock absorption and impact absorption and other characteristics. Silicone foam material can resist vibration in long-term applications, and only a slight change in strength due to stress relaxation occurs. It has excellent reliability in various natural environments, so it has become a Ideal vibration isolation material.

Application range:

•Electronic market: mobile phones, computers, digital cameras, mechanical panels, membrane switches, etc.;

•Automobile market: decorative strips, auto parts, car logos, car perfumes, etc.;

•Household market: hooks, furniture, toys, handicrafts, window gaps, door gap paste, etc.

The company specializes in die-cutting and processing viscose products. The main die-cutting brands are: kts foam, Rogers foam, Inoue foam, 3M tape, Sekisui foam glue, tesa tape, Nitto tape, etc. The specifications can be customized according to customers. Request customization, unlimited meter width, factory equipment.

Die-cutting includes precision stamping, compounding, slitting, rewinding, slitting, die-cutting, etc. It can be used for new energy vehicles, new energy power batteries, lithium batteries, transformers, motors, routers, electronic equipment, waterproof equipment, circuit boards (PCB), home appliances, computers, computers, digital cameras, monitors, automobile manufacturing, electrical appliances, electromagnetics, Communication, electro-acoustic, lighting, LED optoelectronics, hardware, plastics, nameplates, sporting goods, glass curtain walls, furniture, craft gifts, accessories, toys, stationery, molds, construction, assembly, aerospace, machinery, machinery manufacturing, military factories and other industries Provide professional viscose solutions.