Types and applications of polyurethane foam materials

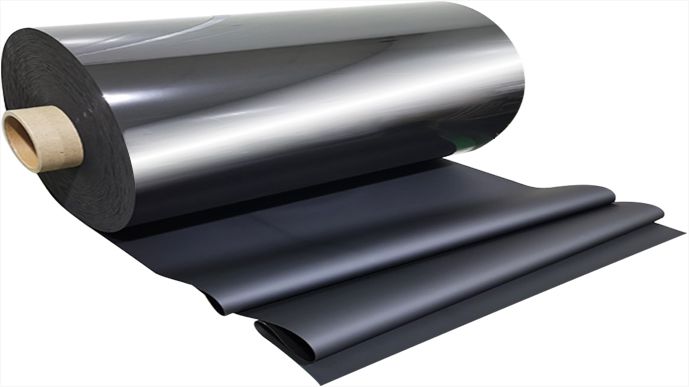

Polyurethane foam definition

Polyurethane foam is a raw material that has been foamed from plastic materials. It is commonly called foam. It is a high polymer material containing many small cells. The solid phase is a high polymer cultivation substrate, and the small cells are filled with other vapors. The foaming ratio is low, the density is high, the key is for shock absorption, and it has a closed function.

Characteristics of foam

• The low working pressure can effectively shield the actual effect, and the shielding efficiency exceeds 90dB.

• It is malleable and light in weight.

• The corrosion-resistant nickel coating prevents electrochemical reactions.

• Low surface loop resistance.

• Quickly pressure-sensitive immobilization.

• Customers can specify the length.

• Many cross-section options.

• UL class fire safety.

• It can be pasted with Mylar sheet (valet double-sided tape) and the product quality is stable.

• High temperature and pressure resistance, not easy to fall off, high tensile and compressive strength.

• After the commercial computer is installed, it will maintain its quality after being tested by the ultra-low temperature -20°C to high temperature 80°C and the cycle time cycle system for three days.

• Easy to use, easy to bend, slim volume, reliable performance.

Common types of foam

1. Korel polyurethane foam

It has high-quality expansion and high resilience, resistance to damp and cold, and acid resistance. It can thoroughly meet the requirements of a variety of natural environments with tightness, kinetic energy digestion and absorption. Polyurethane resin can be pasted on a single layer according to requirements, eliminating the need for self-adhesive work and having a high cost performance. PET-FLLM or paper as the supporting point surface ensures the flatness of the foam, which is suitable for various die-cutting processes.

Features and advantages:

• Excellent resistance to shrinkage and deformation

• Excellent resilience performance

• Dispersion of ground stress

• Resistance to chemicals, moisture in the body, UV resistance

• Maintaining flexibility in harsh natural environments

• It is convenient to form various complicated film cutting parts

• PET full-face glue (optional), which reduces the process flow of glue coating and has the advantage of cost

• PET backing is beneficial to film cutting specifications and stable

application

• Mobile phone speakers, power modules, lampshade sealing, automobiles, electronic equipment and computer communication equipment industries

• Fixed bonding and protection of electronic products, cameras, speakers, liquid crystal displays, signs, etc.

• Battery, connect the plug and compress the foam

• Computer, electronic equipment foot pads, etc.