What is the difference between anti-static foam and ordinary foam?

Anti-static foam and ordinary foam are not only the difference between anti-static and non-anti-static. They are clearly different in materials and main uses.

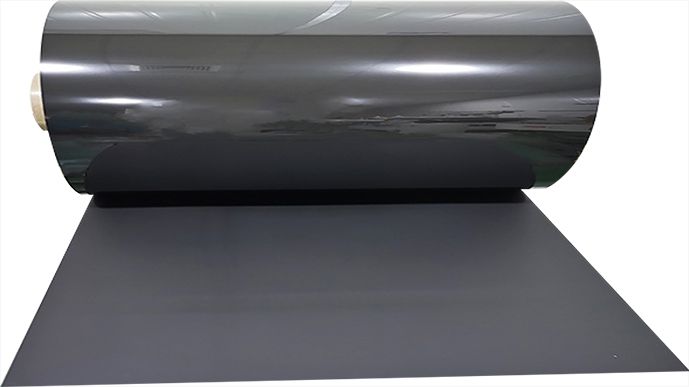

Ordinary foam is a material made of polyurethane foam, a plastic raw material, while anti-static eva foam is molded by special equipment after adding a certain amount of carbon powder during the polyurethane foaming process. The general eva foam does not need to add conductive toner, and it can carry out customized services of different colors according to customer requirements. Anti-static eva foam is generally gray-black at this stage due to high technology.

The resistance value of the surface layer of EVA anti-static cotton ranges from 10 to the 9th power of 10, and the most widely used industry is "electronic equipment". Different electronic equipment has different requirements for resistance. Generally, eva does not have a resistance value, and its application direction is often seen in gift shock-proof packaging. Eva is a highly elastic raw material, and its shock-proof buffer capacity ranks among the top three in the field of packaging products.

In addition to the two aspects of material and main purpose, there is a key difference. Anti-static eva is not to absorb the floating dust in the air, and the general eva is not anti-static and will absorb the floating dust of the gas to accelerate the embrittlement of the product. This is worth noting.