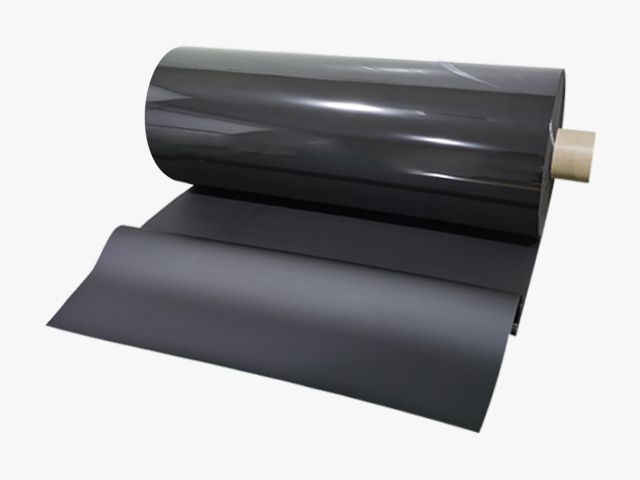

Materials and applications of Rogers Shockpad foam

Rogers Shockpad foam is a high-density soft microporous cushioning material made of polyurethane with a micro-cell structure. It has many outstanding properties, such as flame retardancy, wear resistance, heat resistance, cold resistance, cushioning, sound absorption, shockproof, and sealing, such as excellent resistance to compression deformation, ultra-high resilience, impact resistance, and elastic durability. It is widely used in the shockproof and other aspects of various precision products.

Features of Rogers Shockpad foam

It has excellent sealing properties to avoid gas release and atomization.

Compression deformation resistance, that is, elasticity has durability, which can ensure that accessories are protected from shock for a long time.

It is flame retardant, does not contain harmful substances, does not leave residues, does not pollute equipment, and is not corrosive to metals.

It can be used in a variety of temperature ranges. It can be used from minus 40 degrees Celsius to 90 degrees.

The surface has excellent wettability, is easy to bond, easy to make, and easy to punch.

Engineered polyurethane formula provides a wide modulus range - 2-90 psi@25% deviation - to meet different needs

Advantages of Rogers Shockpad Foam

Anti-compression deformation: not easy to deform after long-term use, maintaining excellent performance.

Ultra-high resilience: quickly restore shape to improve the user experience.

Impact resistance: effectively absorb impact force and protect product safety.

Elastic durability: maintain good elasticity after long-term use.

Sealing performance: prevent air and moisture penetration to ensure product dryness.

Selection of Rogers Shockpad Foam

Material: Choose foam made of high-quality polyurethane raw materials.

Density: Choose foam with appropriate density according to actual needs.

Thickness: Choose foam with appropriate thickness according to product requirements.

Flame retardant performance: ensure that the foam meets international flame retardant standards.

Brand reputation: choose well-known brands to ensure product quality.

Consulting advice: If you have any questions, consult Shenzhen Kaiming for more accurate advice.

Main uses

Panel interlayer: Function - no pollution, prevent loosening, prevent impact noise, prevent adhesion.

Around the LED: prevent light leakage, absorb impact, and improve air tightness.

Around the PCB: absorb impact, absorb vibration, fill gaps, and have heat insulation effect.

Keyboard gasket: rebound, no pollution, and good dimensional stability.

Around the battery: no pollution, absorb impact sound, and improve air tightness.

Foot pad: good friction, no pollution, and good dimensional stability.

Disk drive tail pad: absorb vibration, prevent impact noise, and improve air tightness.

Friction pad: good friction, no pollution, and good dimensional stability.

Disk cover cushion: absorb vibration, block motor noise, shockproof, and improve air tightness.

Around the speaker: prevent noise and fill gaps.

Around the LCD: dustproof, absorb impact, fill gaps, and improve light shielding.

Storage matters

Keep dry: The storage environment should be dry and avoid moisture.

Avoid sunlight: Avoid direct sunlight during storage to prevent material aging.

Neat stacking: Foam should be neatly stacked to avoid deformation under heavy pressure.

Prevent pollution: Be careful to prevent dust, oil and other pollution during storage.

Regular inspection: Check the quality of foam regularly to ensure stable performance.

As mobile devices develop towards slimness and lightness, in order to save design space, designers need to add more components and functions in a small and ultra-thin space, such as display screens, printed circuit boards and other electronic components. However, these components often lack proper impact protection measures. Rogers PORON® ShockPad foam, as a high-performance micro-cell structure polyurethane high-density soft microporous foam material, exhibits excellent impact protection performance.

In order to meet the needs of our customers, Shenzhen Kaiming provides various brands of foam materials and die-cutting services for adhesive materials. Die-cutting includes precision stamping, die-cutting, adhesive backing, compounding, striping, rewinding, slitting processing, die-cutting molding, etc. Provide technical consultation on polyurethane foam materials and adhesive solutions for die-cutting processing. Provide customers with high-quality and cost-effective terminal products