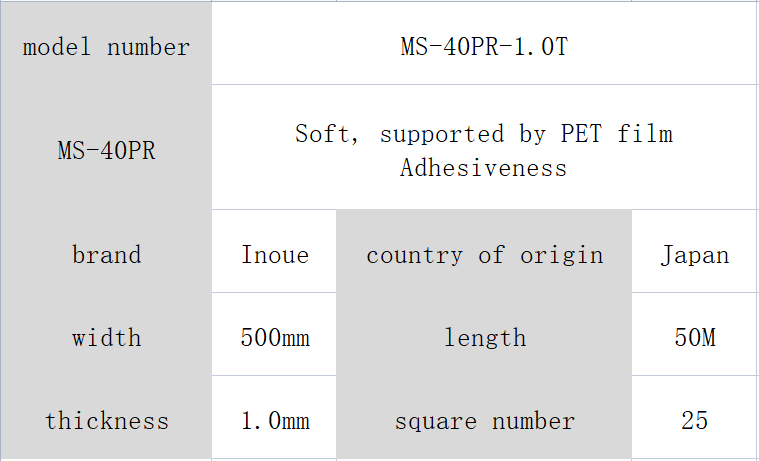

Inoue foam die cutting processing MS-40PR-1.0 MM thickness

Inoue MS-40PR foam is a high-density polyurethane foam material, which is often used for vibration isolation and sound absorption of audio equipment. It has good mechanical strength and sound absorption performance, and also has certain characteristics of water resistance, oil resistance and chemical corrosion resistance.

Hardness: Soft

Thickness: 0.5~1.0mm

Function: PET film support adhesive

Series: PET film support surface special treatment

Function: Using the film integral forming technology, the micro-adhesion can be exerted by removing the PET film. It can be used repeatedly for temporary fixing to improve work efficiency.

Inoue MS-40PR foam die-cutting can be used in various audio equipment, such as speakers, microphones, earphones, etc. Its main function is to isolate and reduce vibration, and it can also play a certain sound absorption effect.

Specifically, Inoue MS-40PR foam die-cutting can be used in the following aspects:

1. Speaker: For speakers, Inoue MS-40PR foam die-cut is usually used to isolate and reduce vibration noise, thereby improving sound quality and volume performance.

2. Microphone: In the microphone manufacturing process, Inoue MS-40PR foam die-cutting is often used to isolate and reduce weak vibration effects, thereby improving recording quality.

3. Earphones: In the manufacture of earphones, Inoue MS-40PR foam die-cutting is usually used to isolate external environmental sounds, thereby improving the listening effect of music or voice.

In conclusion, Inoue MS-40PR foam die-cutting can be widely used in various audio equipment, which helps to improve sound quality and user experience.