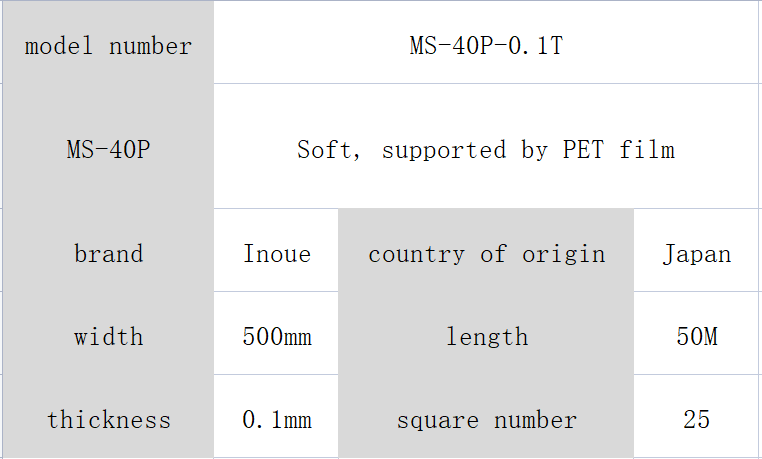

Inoue foam MS-40P-0.10 MM thickness die-cutting processing

Inoue foam MS-40P is a high-performance polyimide foam material with excellent physical and mechanical properties, widely used in aviation, aerospace, national defense, electronics, automobiles and other fields.

Its main features include:

1. High temperature performance: It can withstand temperatures up to 250°C, and still has stable performance at high temperatures.

2. Corrosion resistance: able to withstand the corrosion of various chemical substances.

3. High strength: It has high tensile strength and compressive strength, but also has good rigidity and durability.

4. Lightweight: It is lighter than other materials such as metal, which is beneficial to improve the specific power of the overall weight.

5. Sound insulation: It can effectively isolate external noise and vibration, and reduce noise pollution.

Inoue foam MS-40P is often used in die-cutting to meet the needs of different material applications. Die cutting is the cutting of large materials into desired shapes and sizes.

The application of Inoue foam MS-40P in die-cutting processing includes the following aspects:

1. Electronic products: Inoue foam MS-40P can be used to make sound insulation pads, protective pads, sealing pads, etc. for electronic products such as mobile phones, tablet computers, and cameras.

2. Aerospace: Inoue foam MS-40P can be used to make heat insulation pads, buffer pads, sealing pads, etc. inside aircraft and spacecraft.

3. Automobile: Inoue foam MS-40P can be used to make sound insulation pads, carpet substrates, door panel gaskets, etc. for automotive interiors.

4. Medical equipment: Inoue foam MS-40P can be used to make surgical mattresses, brackets, gaskets and other medical equipment.