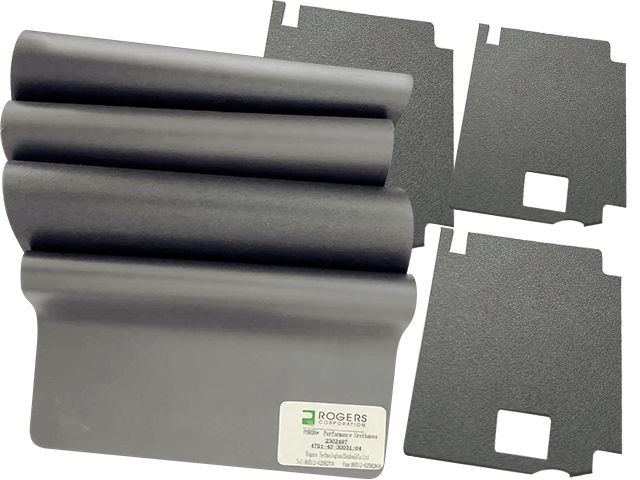

Rogers BF-1000 Ultra Soft Silicone Foam

source: Foam Pageviews: time:Mar 08, 2023

describe:

Rogers BF-1000 ultra-soft porous silicone foam combines compressibility,softness and durability.It is a soft silicone foam with high compressibility.Its light weight and softness make it suitable for a variety of sealing and cushioning applications.

Rogers BF-1000 Ultra Soft Silicone Foam

Rogers BF-1000 ultra-soft porous

silicone foam combines compressibility, softness and durability. It is a soft silicone foam with high compressibility. Its light weight and softness make it suitable for a variety of sealing and cushioning applications in environments where low closure force and tightness are important.

Rogers BF-1000 ultra-soft porous silicone foam is a highly flame-retardant material, ideal for outdoor sealing, protecting electronic products from shock and high heat damage, while providing cushioning and vibration isolation. BF-1000 silicone foam has excellent slow rebound performance and low stress relaxation, which can reduce maintenance costs caused by gasket failure caused by compression set and softening. Its ultra-flexible properties allow designers to seal the enclosure with minimal force while still protecting the device from the environment. Silicone foam provides excellent vibration isolation in electronic components and transportation vehicles. BF-1000 is also ideal for use as an environmental sealant to prevent dust, moisture, air or light leakage in outdoor enclosures such as lighting fixtures, HVAC units, and electronic cabinets.

Common features and benefits of all BISCO porous foam materials:

• Typical density is 12 PCF

• Thickness range from 0.063-1.0 inches

• Not affected by temperature, flexible to adapt to various environments

•The softness provides more effective cushioning protection for the equipment.

• Resistant to UV, ozone, temperature extremes, flame, heat and vibration

•Excellent elasticity and resistance to stress relaxation can reduce maintenance costs.

• High compression can make the material more conformable, which brings more flexibility to the design.

• Comply with FDA specification 21CFR177.2600

•Meet the most stringent flame retardant standards

Application range

•Mobile phone speakers, power modules, lampshade seals, automobiles, electronic equipment and computer communication equipment and other industries

• Fixed bonding and protection of electronic products, cameras, speakers, liquid crystal displays, signs, etc.

•Battery, the filling barrier between the connectors is pressed tightly

•Applications of flame retardant and heat insulation for computers and electronic equipment