describe:

4790-92-12375-04 Rogers polyurethane foam high density,fine and uniform cell structure.Widely used in new energy vehicles,electronic equipment products,mobile phones,notebook computers and other precision products for shock resistance.

Rogers polyurethane foam 4790-92-12375-04

4790-92-12375-04 Rogers

polyurethane foam is a very soft high-performance foam material, suitable for new energy vehicles, electronic equipment products, mobile phones, laptops, refrigerators and air conditioners. It is also suitable for exterior coating, processing and customization and stamping of related products. It can withstand high temperatures of 150°C and low temperatures of minus 40°C. It also plays an irreplaceable role in the die-cutting of electronic accessories.

Rogers foam in the United States has various models to meet various shockproof requirements. It has good compression residual deformation capacity and shock absorption, and has a CELL shape structure with strong compression and rebound force. By using PET, the material has excellent stability and balance, and the material has better sealing ability to curved surfaces. It does not contain polluting, chemical and deforming plasticizers, and it will never pollute other contact materials, and its physical properties will not decrease, and no corrosive gases will be produced.

PORON is a registered trademark of Rogers Corporation, and PORON brand polyurethane foam is a trademark in the foam industry. In China, Rogers Inoue Polymer Materials Co., Ltd., a joint venture between Rogers Corporation of the United States and INOAC Corporation of Japan, produces RIC-PORON brand polyurethane foam materials with high density and fine and uniform cell structure.

performance

Microcellular structure polyurethane is a high-density soft microcellular foam product with many outstanding properties, such as flame retardancy, wear resistance, heat resistance, cold resistance, cushioning, sound absorption, shock resistance, sealing, such as excellent compression deformation resistance, super High resilience, impact resistance, elastic durability, etc. It is widely used in various precision products for shockproof and other functions.

Application field

Polyurethane foam is widely used in the cushioning of new energy vehicles, electronic equipment, and aerospace and rail vehicle interiors. Built for durability and reliability, it's built to last. Polyurethane foam material has outstanding resilience, good vibration damping and impact absorption performance, and excellent waterproof sealing effect. Available in a wide range of durometers and thicknesses, they are easily compressible for applications requiring high flexibility.

The main purpose

• Panel interlayer: function - no pollution, prevent loosening, prevent impact noise, prevent adhesion.

• Around the LED: prevent light leakage, absorb impact, and improve airtightness.

• PCB lower periphery: shock absorption, shock absorption, gap filling, heat insulation effect.

•Keyboard spacers: rebound, no pollution, good dimensional stability.

• Around the battery: no pollution, absorb impact sound, and improve airtightness.

• Foot pad: good friction, no pollution, good dimensional stability.

• Disk drive tail pad: Absorb shock, prevent impact noise, and improve air tightness.

•Friction gasket: good friction, no pollution, good dimensional stability.

•Cover cover cushion: Absorb vibration, block motor noise, shockproof, and improve airtightness.

• Around the speaker: prevent noise and fill gaps.

• Around the LCD: Dustproof, shock absorbing, gap filling, and light-shielding enhancement.

main features

•Excellent sealing to avoid gas release and atomization.

•Resistance to compression deformation, that is, the elasticity is durable, which can ensure the long-term shock protection of accessories.

• It is flame retardant, does not contain harmful substances, does not leave residues, does not pollute equipment, and is not corrosive to metals.

• Can be used in a variety of temperature ranges. It can be used from minus 40 degrees Celsius to 90 degrees.

•The surface has excellent wettability, easy to bond, easy to make, and easy to die-cut.

•Engineered urethane formulations offer a broad modulus range for greater design flexibility

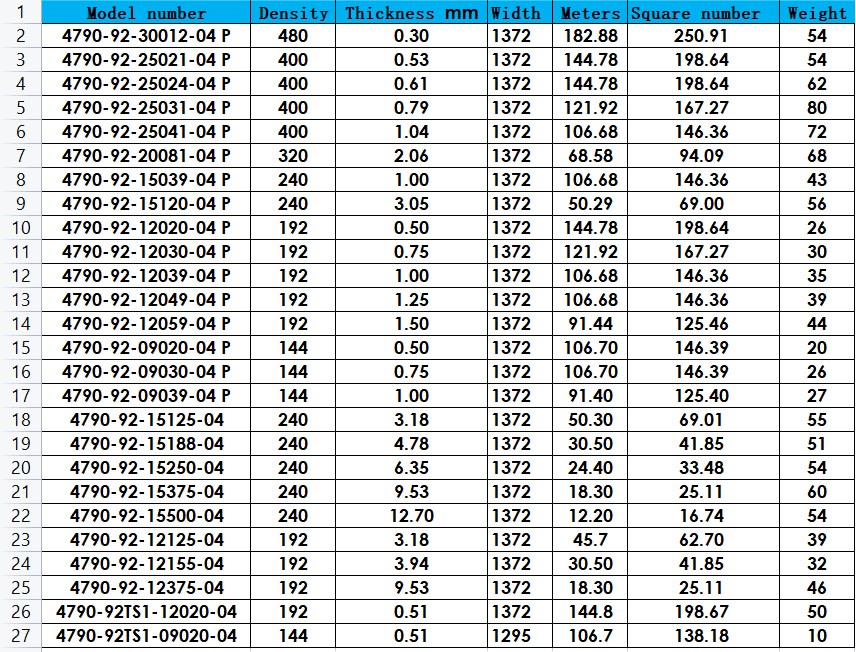

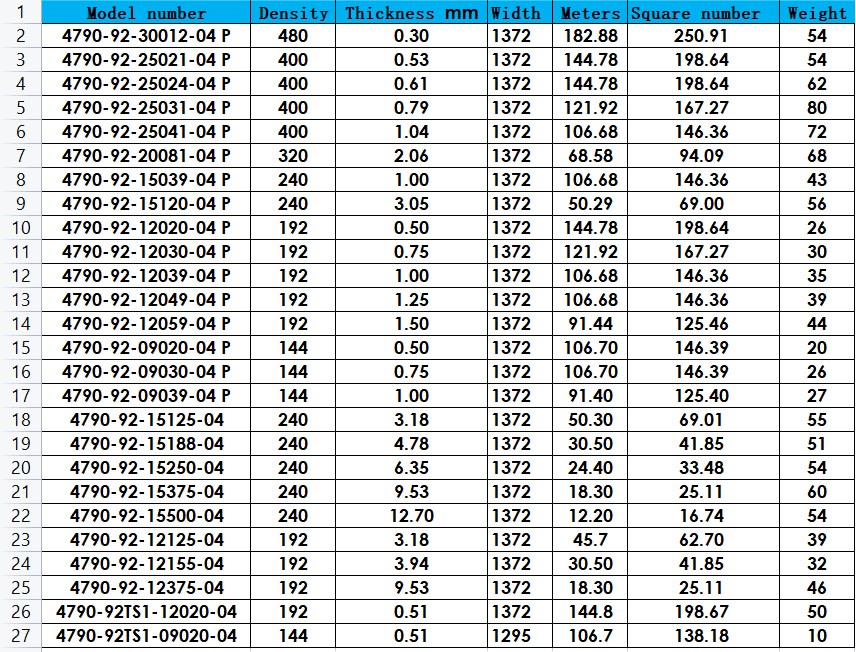

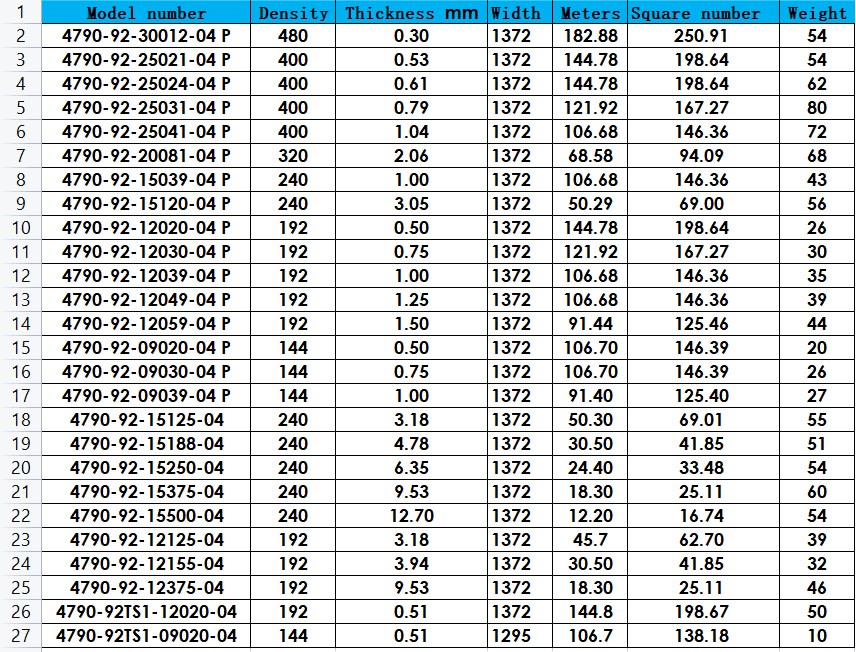

Rogers polyurethane foam 4790-92 series conventional models