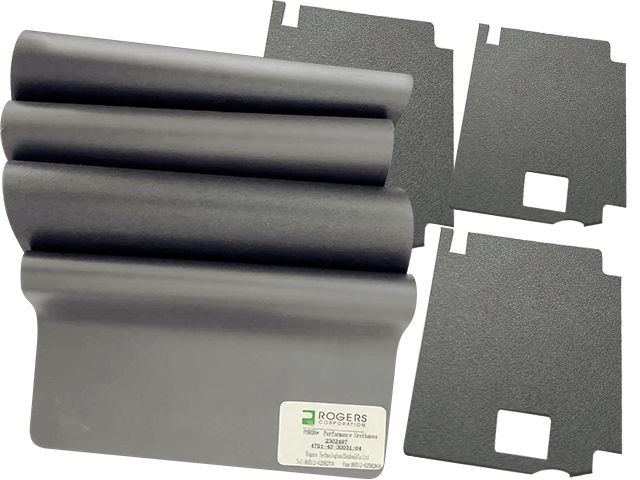

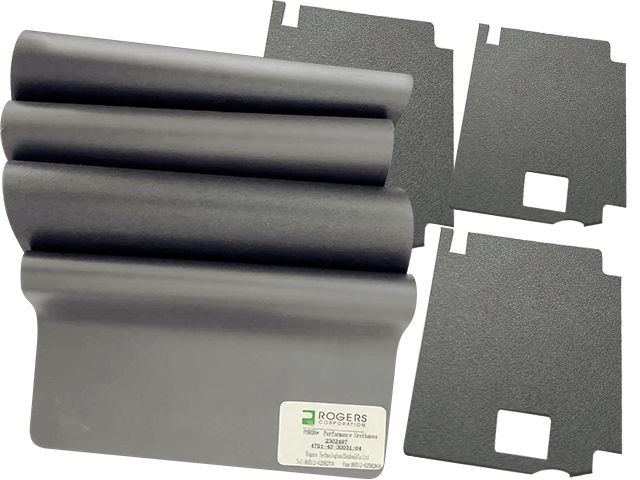

Ultra-thin cushioning material: Rogers PORON ShockPad Foam

source: Foam Pageviews: time:Jun 14, 2024

describe:

Rogers PORON ShockPad Foam is a high-performance cushioning material developed by Rogers Corporation. This structure gives PORON ShockPad Foam excellent cushioning performance, making it a cushioning material for many high-end devices and products.

Ultra-thin cushioning material: Rogers PORON ShockPad Foam

Rogers PORON ShockPad Foam is a high-performance cushioning material developed by Rogers Corporation. It uses advanced microporous foaming technology to evenly distribute tiny bubbles inside the material, forming a lightweight and resilient structure. This structure gives PORON ShockPad Foam excellent cushioning performance, making it a cushioning material for many high-end devices and products.

Features of PORON ShockPad Foam:

Ultra-thin and light: PORON ShockPad Foam has an extremely thin thickness and light weight, which can easily meet the needs of lightweight equipment.

Excellent cushioning: The unique microporous foaming structure enables it to effectively absorb and disperse impact forces, providing excellent cushioning protection for the equipment.

Durable and stable: The material has good durability and stability, and can maintain excellent performance even under long-term use.

High resilience: The material has excellent resilience and can quickly return to its original state, maintaining its performance even after long-term use.

Chemical corrosion resistance: It has good resistance to most chemicals and is suitable for use in various environments.

Compression set resistance: It can maintain its shape and performance even under continuous pressure and is not easy to deform.

Environmentally friendly and safe: PORON ShockPad foam meets environmental standards, is non-toxic and harmless, and can be used with confidence.

The advantages of PORON ShockPad foam over other cushioning materials are:

Excellent performance stability: It is not affected by external factors such as temperature and humidity, and always maintains stable performance.

Unique material construction: The advanced material process is used to make it have excellent elasticity and durability.

Versatility: It can be widely used in various industries and fields to meet the needs of different scenarios.

Choosing the right PORON ShockPad foam product is crucial. Rogers offers a variety of foam products with different hardness and thickness to meet the needs of different equipment. When choosing, please consider the following factors:

Application requirements: According to the specific application scenarios and requirements, select the appropriate size, thickness, hardness and other parameters.

Performance requirements: According to the required impact absorption performance and comfort requirements, select the appropriate material model and specifications.

Cost-effectiveness: Considering factors such as performance, quality and price, choose products with high cost performance.

Rogers PORON ShockPad foam is widely used in:

Consumer electronics: shockproof and protection for the edges and corners of mobile phones, tablets, laptops and other devices.

Sports equipment: cushioning layer of sports protective equipment such as helmets and protective gear.

Medical equipment: used for shockproof and protection of medical devices to ensure the safety of equipment during transportation and use.

Automotive industry: cushioning material used for automotive interiors to improve riding comfort and safety.

Rogers PORON ShockPad foam material can be processed into foam products of various shapes and sizes through die-cutting process. It is widely used in various electronic devices such as mobile phones, tablets, laptops, smart wearable devices, etc. In addition, it is also widely used in communication equipment, medical equipment, automotive parts and other fields.

In order to meet the needs of our customers, Shenzhen Kaiming provides various brands of foam materials and die-cutting services for adhesive materials. Die-cutting includes precision stamping, die-cutting, adhesive, compounding, striping, rewinding, slitting processing, die-cutting molding, etc. Provide technical consultation on polyurethane foam materials and adhesive solutions for die-cutting processing. Provide customers with high-quality and cost-effective terminal products.