Application of silicone foam on aircraft

Silicone foam is used in key support pads for important tasks in aviation equipment. It provides consistent rebound support in extremely harsh environments to ensure the long-lasting and stable operation of the equipment.

An aerospace equipment manufacturer needs to use support foam when designing the keys in the cockpit of the aircraft to provide stable and lasting rebound force for the keys. The thickness and width of the foam in application are both about 1mm. Combining the special applications of aerospace and the strict requirements of customers, the foam needs to have the following properties:

1. Good temperature resistance;

2. Excellent fire and flame retardant ability;

3. Long-lasting rebound force;

4. Material cells are uniform and stable.

Uniform and small foaming is a problem for most polyurethane foams on the market, and it is necessary to achieve fire and flame retardant requirements at such a thin thickness.

solution

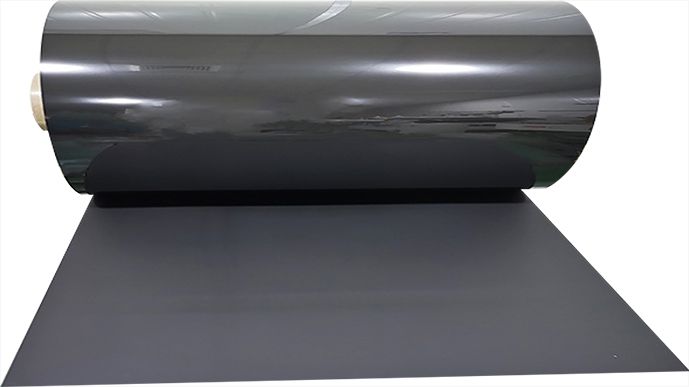

Our silicone foam series of open-cell ultra-soft silicone foam is the main product for sealing and supporting applications. It has a stable and detailed foam structure, strong pore wall, and can reach UL94V-0 as thin as 0.8mm. Flame retardant grade, able to work normally in the range of -55-150℃. At 40% compression, after millions of fatigue compression tests, the compression rebound loss of less than 8% compared with the competitor's compression rebound force loss of more than 30% enables the product to maintain stable performance after long-term repeated compression. It is very suitable for the application needs of customers in this harsh environment. After several samples and repeated verification tests, the customer is very satisfied with the silicone foam produced by our company. At present, the customer and the mass purchase of our silicone foam material have entered the mass production stage.

Customer needs, our responsibilities

Shenzhen Kaiming Technology Co., Ltd. is a comprehensive enterprise integrating R&D, production, sales and service. Provide one-stop solutions for new energy, railway, aerospace and other industries. Independent research and development capabilities and complete testing equipment enable products not only to have excellent performance, but also to provide customers with customized product services.